Microbiology and Biochemistry

Introduction

The spontaneous fermentation of lambic is the process by which non-cultivated yeasts and bacteria present in the environment around the wort take up residence in the beer and which are responsible for its fermentation and many of its final characteristics. In contrast to the controlled fermentation found in most other modern beers, spontaneous fermentation involves many different organisms and proceeds through at least four distinct, but often overlapping, stages, each characterized by the dominance of a different set of microbes which are responsible for different aspects of the finished lambic. The rapid rate of evolution of these microorganisms makes them unique to their geographic, chemical, and even seasonal environment.

Spontaneous fermentation

The spontaneous fermentation of lambic is a complex process involving a succession of bacteria and yeasts that progresses along with the chemical changes that occur during fermentation.[1] The spontaneous fermentation process has shown considerable variability even among different barrels of beer from the same brewery,[2] though all spontaneously fermented beers appear to follow a general sequence of microbes, which can be broken into four distinct stages:[3][4][2]

- An enteric stage, starting around three days after the boil and ending between 30 and 90 days, in which enteric bacteria dominate.

- Saccharomyces dominance, lasting from 3 to about 30 weeks, in which Saccharomyces cerevisiae and other Saccharomyces species dominate the beer's yeast flora.

- Pediococcus dominance, lasting from 2 months onward, in which Pediococcus and other lactic acid bacteria dominate the bacterial flora.

- Brettanomyces dominance, lasting from 4 to 8 months onward.

A fifth stage of fermentation in the bottle after most Brettanomyces fermentation is complete may exist, however research towards the long-term aging of lambic is scant. The various stages of fermentation have a significant degree of overlap with one another as the yeast and bacterial populations live alongside one another, and the times at which they begin and end can vary by up to several months.[3]

The microbes present in lambic may come from a variety of sources in the brewhouse and the surrounding environment, including the surrounding air, the walls and ceilings of the brewhouse, and the wooden barrels the beer is kept in.[3] The organisms in lambic are present in different parts of the environment and it is likely that the organisms responsible for lambic come from a number of different places.

Stages of Lambic fermentation

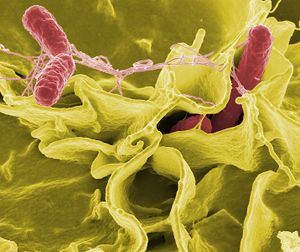

The enteric stage

Lambic wort arrives in the koelschip at approximately 5% sugar per weight of water, along with an assortment of proteins and fatty acids and other compounds.[5] Negligible ethanol is present prior to fermentation, nor is there much of the organic acids that will give lambic its characteristic tartness; the wort has a pH around 5, which is similar to the wort of other beers.[4] Enteric bacteria, including Enterobacter hormaechei, E. kobei, Klebsiella pneumoniae, and Escherichia coli, are the first to gain a foothold in this environment, with significant numbers found after three to four days. The enteric bacteria primarily consume glucose, which reduces the gravity of the wort from ~1.050 to ~1.040 after the first three weeks.

Enteric bacteria are responsible for the production of acetic acid, and the pH of the wort falls from around 5 to 4.5 in the first week of fermentation. The 40 to 120 mg/L acetic acid found in the wort after the first week is very close to the amount found in the final product.[4] [6] Significant changes to the concentration of acetic acid should not occur until the ethanol has a chance to oxidize in aging in the bottle over many years or even decades.[7][8] The pellicle that forms on the top of the wort may be the product of acetobacteria during the enteric phase,[9] though most other sources indicate that the pellicle is the result of Brettanomyces (with Pichia and Candida).[9]

Low pH (below ~4.5) and an ethanol concentration higher than ~2% by volume is a hostile environment to the enterobacteria, and Saccharomyces species are able to dominate the flora in the wort once these conditions occur around 30 to 60 days into fermentation.

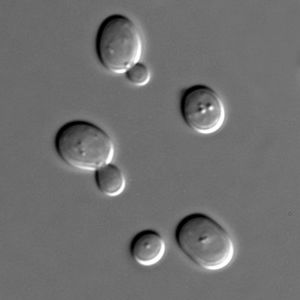

Saccharomyces dominance

After the pH falls below ~4.5 and the alcohol content rises over ~2%, Saccharomyces species take over as the dominant organisms in the wort, though Saccharomyces is present in large numbers well prior to the disappearance of the enterobacteria. Saccharomyces will remain dominant until at least 6 to 8 months into fermentation, and will maintain a presence, though no longer active, throughout fermentation. Despite Saccharomyces' importance to the fermentation of lambic, its concentrations remain below 107 cells/mL of wort, which is considerably lower than the 108 cells/mL found in commercial beers.[4][9]

As in controlled fermentation, Saccharomyces is responsible for most ethanol production and attenuation in lambic. The yeasts consume all the major sugars found in lambic wort (glucose, maltose, and some maltotriose). By the end of the Saccharomyces phase around 8 months, the ethanol content of the beer stabilizes at 5 to 7% by volume and will remain around that value until the end of fermentation.[9][4] Attenuation after Saccharomyces fermentation reaches 60 to 65%, which is known as the "attenuation limit" for conventional beers. Despite being responsible for most of the ethanol in lambic, yeasts of the Saccharomyces genus are not responsible for most of the aroma and flavor compounds that give lambic its distinct sensory characteristics.[10]

Other bacteria and yeasts also thrive during the Saccharomyces phase. Kloeckera and Debaryomyces both survive in considerable numbers alongside Saccharomyces.[4] [2] In the case of Kloeckera, the growth begins prior to Saccharomyces in the first days of fermentation, but are overgrown by Saccharomyces in the following weeks.

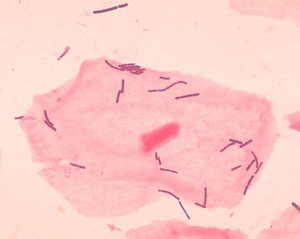

Pediococcus dominance

After the changing environment of the wort ends the growth of the enteric bacteria around 30 to 60 days, bacteria of the pediococcus come to dominate the bacterial flora. Lactobacillus can also be found in the wort in large numbers at this time, and both genuses are responsible for most of the lactic acid in lambic. Collectively these bacteria are known as the lactic acid bacteria.

The lactic acid bacteria increase in number until around month 7, achieving concentrations of 104 cells/mL wort, which is thought to coincide with the onset of summer and warmer temperatures.[2] With this in mind, it is thought that the increase in lactic acid bacteria be delayed or hastened by decreasing or increasing the storage temperatures, respectively.[2][3]

Interestingly, lactic acid bacteria have been implicated in racemizing amino acids in beer, causing lambic (and other beers which make use of lactic acid bacteria such as Berliner Wiesse) to have a high percentage of right-handed amino acid stereoisomers relative to both their starting materials and other beers.[5]

Brettanomyces dominance

Brettanomyces inherits the role of most prominent yeast genera from Saccharomyces around 8 months, and continues consuming sugars in the wort. Final attenuation can reach over 80% in lambic through the continued action of Brettanomyces, which is often referred to as "overattenuation" or "superattenuation". This is greater than is usually possible with Saccharomyces alone, as Brettanomyces is able to metabolise sugars that Saccharomyces cannot, generally known as "dextrins". In addition, brettanomyces can metabolise laminarin and pectin, and has a greater affinity for the amino acid proline than Saccharomyces[11]. There is some inter-strain variability on what sugars Brettanomyces can metabolize (arbutin, β-methyl-D-glucoside, et al. are only metabolized by some strains of Brettanomyces.)[11]

Brettanomyces has been implicated in producing most of the aroma compounds in Lambic.[9] Sensory-significant quantities of ethyl acetate and ethyl lactate form at this time from ethanol entering into an ester bond with acetic and lactic acid, respectively. In addition, ethylphenols formed from hydroxycinammic acid -- found in the grain used to make the wort -- contribute an odor often described as "horse sweat", "barnyard", or "leather" [11] [12]. The esterization process is greatly helped by the enzyme esterase provided by Brettanomyces. However, the enzymatic esterization is highly reversible and esters found in high concentrations in the lambic prior to the presence of the esterase will often achieve a lower equilibrium at the end of fermentation. This is the case with iso-amyl acetate, which is produced by Saccharomyces and is a characteristic odor compound in many other beers.

Tetrahydropyridines (THPs) produced by Brettanomyces (as well as some Lactobacilli) have a wide variety of odors and give lambic much of its "mousey" aroma, as well as cider- and horse-like aromas, though the concentrations and thus smells of THPs are variable.[13] Other important odor and flavor compounds produced by Brettanomyces include 4-ethylphenol, 4-ethylguaiacol, and isovaleric acid. 4-ethylphenol produces barnyard and horsey flavors which can taste like Band-aids in higher concentrations. 4-ethylguaiacol lends spicier flavors of bacon and cloves and can be smoky, while isovaleric acid gives lambic its sweaty and cheesy flavors and odors.

Around 16 months after the start of fermentation, during this stage, the pH of the beer reaches a minimum of about 3.0, which then rises slightly in the following months to ~3.2 to 3.4,[14][4][9] perhaps due to the enzymatic esterification of organic acids by Brettanomyces.

Refermentation in the bottle

Gueuze and other lambic bottled with either some residual sugar left unfermented at the time of bottling or added priming sugars will undergo significant fermentation in the bottle, though all unpasteurized lambic will continue to ferment to some degree there. For lambic bottled after about 8 months without additional sugar, the fermentation in the bottle progresses much as an extension of the Brettanomyces stage of fermentation and negligible carbon dioxide and ethanol production occurs, leaving most of this lambic still. For lambic bottled younger and those with additional fermentable sugars added at bottling, considerable fermentation by Saccharomyces occurs in the bottle, causing marked increases in ethanol and the production of carbon dioxide, leading to a carbonated product.[4]

The reactivation of Saccharomyces fermentation at the addition of additional sugar indicates that the dominance of Brettanomyces is brought about by Brettanomyces' ability to ferment sugars that Saccharomyces cannot. Once Saccharomyces has consumed most of the available glucose and other simple sugars in the wort, it goes dormant, though does not die completely, and Brettanomyces is free to assume the role of primary yeast in the wort. Upon the re-introduction of the simple sugars, the faster-growing Saccharomyces once again flourishes, until the fermentable sugar is again consumed and Brettanomyces and its other associated yeasts can once again resume the slow process of the final fermentation.

Continued aging

The ongoing process of lambic aging after its maturation is a very complex process and has both purely chemical as well as biochemical aspects. Much of the present literature is general to all beer.

Eventually even the slow-fermenting Brettanomyces runs out of fermentable sugars and fermentation draws to a prolonged close. The beer will continue to change and evolve over time, though minimal interaction with active yeast occurs. This stage is marked by oxidation and breakdown of the more complex parts of the yeast itself.[15] [16]

The decomposition of the yeast progresses primarily through the action of their own enzymes in a process called autolysis. Autolysis releases a large number of other enzymes, which has the secondary effect of breaking down many other components of the beer.[7] The release of esterase leads to the increased destruction of iso-amyl acetate and other esters, causing a loss of its light, fruity odor. Not all esters are broken down by this process, and a number of esters are formed during aging. These include ethyl 3-methyl-butyrate and ethyl 2-methyl-butyrate which contribute a light floral or even tropical fruit odor.[17][18] The release of proteases by autolysis causes a breakdown of long protein chains, with its concordant thinning of mouthfeel and reduction in head. While autolysis is often seen as undesirable, it can contribute to a pleasant mouthfeel as well as some of the characteristic flavors found in very old lambic.[19]

While oxidation can occur rapidly due to a break in the fidelity of the seal at the cork, oxidation can still occur without the passage of oxygen through the cork or significant oxygen gas in the headspace due to the transfer of oxygen from an oxidizing compound in the wort to others. The act of losing an oxygen, or more generally, of losing electrons, is called reduction.

Production of (E)-2-nonenal (as well as other linear aldehydes) has been implicated as being of primary importance to the long-term oxidation of flavor compounds in beer,[20] which leads to a characteristic flavor of oxidized beer, commonly described as being of "wet cardboard". However, many other processes and compounds are important to the aging of beer as well.

The Maillard reaction, also responsible for the browning of toast and steak among many other things, occurs in the unfermented reducing sugars left in the beer during extended aging, leading to a darker brown color as well as a slight burnt toast flavor.[7]

Many other reactions occur as lambic ages that are not elaborated upon here in the interests of brevity.

Sources of the microbes in Lambic

The microbes found in lambic may come from a variety of sources, as nearly every surface and even the air found in the brewery are teeming with life. While the air above the koelschip is often cited as the source of the microorganisms in lambic, other sources are now known to play a significant role.

While there are many potential places that the wort can acquire its characteristic flora, some primary reservoirs to consider are:

- The air over the wort and in the cellar where the wort is aged.

- The ceiling and walls of the facility, from which microorganisms attached to dust or condensation from the hot wort may find their way into the beer.

- The surfaces of the barrels, both interior and exterior, as contamination from the exterior may occur during transfer of the wort.

Each reservoir potentially contributes different organisms to the lambic. Samples taken from a lambic brewery indicate that the air above the koelschip and in the cellar is the primary source of the bacteria in the lambic, while the barrels host much of the yeast, though some yeasts are found in the air and some bacteria come from the barrels as well. [2]

Geographical variation

The rapid reproduction of the microorganisms found in lambic also lends to them the ability to evolve on much shorter timescales than those of macroorganisms. Combined with the flora found in lambic (and other spontaneous fermentations) being largely resident inside each brewery,[3][4] it is reasonable to assume that even the slight geographic separation found between the facilities within the Pajottenland will lead to markedly different strains of bacteria and yeasts responsible for lambic fermentation after several years of operation. Further, brettanomyces isolated from different sources from the same location have shown significant genetic variability[11] [21], indicating that slightly different handling methodologies and even the surrounding architecture may have an effect on the final product. Thus, it is reasonable to assume that at least part of the distinct flavors found in the lambics of each brewery are due to divergent evolution in their respective microbiomes,[10] though little literature currently exists in this area. For other breweries, "house strains" developed by propagating favorite yeasts often over a period of years and even decades is commonplace, and often accounts for much of a brewery's specific taste.

Conversely, it has been found that spontaneous fermentations in similar worts in other parts of the world follow similar overall trends.[3] Yeasts such as Saccharomyces and Brettanomyces and bacteria such as the enterobacteria and Pediococcus are cosmopolitan throughout the world, and all are similar enough to be classified into the same genus by both phenotype and genotype. However, the large degree of geographic separation coupled with the rapid evolutionary rates of these organisms will still lead to measurable changes in both. This is highlighted in the fact that while many lambic-like beers have been brewed in other parts of the world, and are often very similar to lambic itself, they still possess noticeably different sensory characteristics. This can be likened to terroir in wine, as the local microbiome in one location will produce a similar, but not identical, product to that in another location.

As an example, Brettanomyces shows significant genomic variation between strains, as well as a corresponding variability in their metabolisms, indicating that different strains of Brettanomyces bruxellensis will lend markedly different sensory characteristics to lambic.[22][21][23][24][25]

Seasonal variation

Little research exists correlating the season of brewing to changes in the microbiology and chemistry of lambic; however, a delay in the appearance of the late-fermentation bacterial flora in lambic was observed when fermentation started earlier in the brewing season, leading to cooler fermentation temperatures.[2] The flora were indistinguishible after 18 months.

Similarly, a study on spontaneously fermented ales in the United States revealed marked differences between ales brewed in the spring versus those in the winter.[3] The flora broadly follow the same pattern of succession regardless of the season of inoculation, although genetic analysis showed distinct differences between the flora responsible for fermentation occurring in the spring versus the winter. The differences between the organisms found in the wort inoculated at different seasons were largest in the early stages of fermentation and by 36 weeks, there was no longer a significant difference in the flora of in either season's wort.

Other spontaneous fermentations

Spontaneous fermentation is important to a wide variety of foodstuffs other than lambic, ranging from very similar modern beers brewed in other parts of the world to cheeses and pickled vegetables.

American Coolship Ale, American Wild Ale, etc.

Spontaneously fermented beers from the United States form a group of beers referred to as American Coolship Ales (or ACAs), American Wild Ales (or AWAs), among other names.[3] Spontaneously fermented beers from other parts of the world are occasionally referred to as "American Wild Ales" as well, though it is unclear if there is any reason to associate any arbitrary spontaneous or even mixed fermentation beer that doesn't fall into another existing style with the United States. At present, there are few satisfactory naming conventions for these beers.

ACAs vary in their intended similarity to lambic, with some American producers even going so far as to label their beers "lambics", while other ACAs bear little in common with lambic besides spontaneous fermentation. Due to the geographical separation between the United States and Belgium and the large variations in yeast and bacteria genetics between these different populations, even an ACA wort carefully prepared to be very similar to that of lambic will yield notably different results after fermentation, even if the overall experience of the two styles of beer is similar.[3] [6] [4]

Spontaneous fermentation in other traditional drinks and foods

Other spontaneous fermentations exist as well, such as Chicha, a corn-based lightly alcoholic drink indigenous to the Andes. Much like the spontaneous fermentation of lambic, Chicha possesses its own set of yeasts, dominated by strains of Saccharomyces responsible for its unique characteristics.[26]

Brettanomyces and other wild organisms, despite often being spoilage organisms in wine, are responsible for some major sensory characteristics of some wine styles.[27][28] Other minor yeasts found in lambic, such as Pichia and Kloeckera, have also been found in unspoiled wine.[27][28]

Conclusion

Spontaneous fermentation is a complex process compared to the cultured fermentations of other beers. Several genera of both yeast and bacteria are involved in making the final product. The order in which these organisms dominate the flora allows us to divide the fermentation process into several distinct stages. We have chosen to divide the process into four distinct parts. First, colonization by enteric bacteria, which is responsible for production of acetic acid in the wort, followed by the growth of the yeasts Kloeckera and then Saccharomyces, which ferment most of the simple sugars and produce the majority of the ethanol in lambic. During the Saccharomyces dominanace of the yeast flora, the bacterial flora switch to primarily lactic acid bacteria, which do exactly what you'd expect something with that name to do. At the end of fermentation, Brettanomyces comes to dominate the yeast flora, and the slow fermentation by these organisms is responsible for many of the odors and flavors associated with lambic. The aging process then continues well after the beer is bottled. Geographic and seasonal variation, coupled with the "wild" nature of spontaneous fermentation in general, conspires to make lambic a truly unique product.

References

- ↑ Jef Van den Steen, Geuze & Kriek: The Secret of Lambic Beer, 2012

- ↑ 2.0 2.1 2.2 2.3 2.4 2.5 2.6 F. Spitaels, A. D. Wieme, M. Janssens, M. Aerts, H.-M. Daniel, A. Van Landschoot, L. De Vuyst, P. Vandamme | The Microbial Diversity of Traditional Spontaneously Fermented Lambic Beer, 2000

- ↑ 3.0 3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 Nicholas A. Bokulich, Charles W. Bamforth, David A. Mills. | Brewhouse-Resident Microbiota Are Responsible for Multi-Stage Fermentation of American Coolship Ale, PLoS One, 7(4), 2012

- ↑ 4.00 4.01 4.02 4.03 4.04 4.05 4.06 4.07 4.08 4.09 D. Van Oevelen, M. Spaepen, P. Timmermans and H. Verachtert, |MICROBIOLOGICAL ASPECTS OF SPONTANEOUS WORT FERMENTATION IN THE PRODUCTION OF LAMBIC AND GUEUZE, 1977

- ↑ 5.0 5.1 T. Erbe and H. Brückner, | Chromatographic determination of amino acid enantiomers in beers and raw materials used for their manufacture, 2000

- ↑ 6.0 6.1 J. Edwards and A. DiCaprio. | When Beer Goes Sour: An NMR Investigation, Mestrelab MNova Users Meeting, SMASH – Atlanta, GA, September 7, 2014

- ↑ 7.0 7.1 7.2 B. Vanderhaegen, H. Neven, H. Verachtert, G. Derdelinckx | The chemistry of beer aging – a critical review, 2006

- ↑ Werner Van Obberghen, 2. Het algemene productieproces van bier

- ↑ 9.0 9.1 9.2 9.3 9.4 Jean-Xavier Guinard, Classic Beer Styles: Lambic, 1990

- ↑ 10.0 10.1 K. A. T. Witrick | Characterization of aroma and flavor compounds present in lambic (gueuze) beer, 2012

- ↑ 11.0 11.1 11.2 11.3 S. Crawels et. al. | Comparative phenomics and targeted use of genomics reveals variation in carbon and nitrogen assimilation among different Brettanomyces bruxellensis strains, 2015

- ↑ M. Lentz and C. Harris. | Analysis of Growth Inhibition and Metabolism of Hydroxycinnamic Acids by Brewing and Spoilage Strains of Brettanomyces Yeast, 2015

- ↑ T. Heresztyn | Formation of Substituted Tetrahydropyridines by Species of Brettanomyces and Lactobacillus Isolated from Mousy Wines, 1986

- ↑ | Embrace the Funk's list of beer pH

- ↑ C. E. Dalgliesh, Flavour stability, | Proceedings of the European Brewery Convention Congress, 1977

- ↑ B. Vanderhaegen, H. Neven, H. Verachtert, and G. Derdelinckx, |The chemistry of beer aging – a critical review, 2006

- ↑ J. J. Bohmann | Zum Alterungsverhalten des Bieres. 4 Teil, Kombinierte Alterungsversuche durch Begasung mit Kohlendioxid, Stickstoff, Luft und Sauerstoff, 1985

- ↑ J. J. Bohmann | Zum Alterungsverhalten des Bieres. 3. Teil, Der Einfluß der Strahlungsbelastung, dargestellt am Beispiel 2-Methyl-2-buten und Isopren, 1985

- ↑ J. Robinson (ed) "The Oxford Companion to Wine" Third Edition pg 54 Oxford University Press 2006 ISBN 0-19-860990-6

- ↑ A. M. Jamieson, E. C. Chen, and J. E. A. Van Gheluwe, A study of the cardboard flavour in beer by gas chromatography, | Proceedings of the American Society of Brewing Chemists, 1969

- ↑ 21.0 21.1 A. Borneman et. al. | Insights into the Dekkera bruxellensis Genomic Landscape: Comparative Genomics Reveals Variations in Ploidy and Nutrient Utilisation Potential amongst Wine Isolates, 2014

- ↑ L. Conterno, C. M. L. Joseph, T. J. Arvik, T. Henick-Kling, and L. F. Bisson | Genetic and Physiological Characterization of Brettanomyces bruxellensis Strains Isolated from Wines, 2006

- ↑ Brettanomyces Project Dissertation, Chad Michael Yakobson

- ↑ C. D. Curtin, J. R. Bellon, P. A. Henschke, P. W. Godden, and M. A. de Barros Lopes Genetic diversity of Dekkera bruxellensis yeasts isolated from Australian wineries, 2007

- ↑ M. Agnolucci, I. Vigentini, G. Capurso, A. Merico, A. Tirelli, C. Compagno, R. Foschino, M. Nuti | Genetic diversity and physiological traits of Brettanomyces bruxellensis strains isolated from Tuscan Sangiovese wines, 2009

- ↑ J. A. Vallejoa, P. Mirandaa, J. D. Flores-Félixb, F. Sánchez-Juanesc, J. M. Ageitosa, J. M. González-Buitragoc, E. Velázquezb, T. G. Villaa, | Atypical yeasts identified as Saccharomyces cerevisiae by MALDI-TOF MS and gene sequencing are the main responsible of fermentation of chicha, a traditional beverage from Peru, 2013

- ↑ 27.0 27.1 M. Tristezza, C. Vetrano, G. Bleve, G. Spano, V. Capozzi, A. Logrieco, G. Mita, F. Grieco | Biodiversity and safety aspects of yeast strains characterized from vineyards and spontaneous fermentations in the Apulia Region, Italy, 2013

- ↑ 28.0 28.1 K. Medina, E. Boido, L. Fariña, O. Gioia, M.E. Gomez, M. Barquet, C. Gaggero, E. Dellacassa, F. Carrau | Increased flavour diversity of Chardonnay wines by spontaneous fermentation and co-fermentation with Hanseniaspora vineae, 2013